| Model: | 6305 6305-ZZ 6305-2RS |

|---|---|

| Min. Order: | 5000 Piece/Pieces |

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

| Production Capacity: | 0.3 MILLION PCS PER... |

| Packing: | TUBE | Delivery Date: | 20 DAYS |

|---|---|---|---|

| Brand Name: | JUF | SIZE: | 25*62*17 |

| MATERIAL: | GCR15 SAE52100 | GREASE: | JUF3# |

| PRECISION GRADE: | P0/P6/P5 | FITNESS: | C0/C3 |

| OEM SERVICE: | AVALABLE | PACKING: | TUBE |

| MARKING: | JUF or NEUTRAL or BLANK |

| Item No. | d(mm) | D(mm) | B(mm) | rmin | rlmin | Cr(KN) | Cor(KN) | Weight(kg) |

| 6300 | 10 | 35 | 11 | 0.6 | 0.5 | 7.65 | 3.47 | 0.0532 |

| 6301 | 12 | 37 | 12 | 1 | 0.5 | 9.72 | 5.09 | 0.0586 |

| 6302 | 15 | 42 | 13 | 1 | 0.5 | 11.44 | 5.43 | 0.0804 |

| 6303 | 17 | 47 | 14 | 1 | 0.5 | 13.58 | 6.58 | 0.1096 |

| 6304 | 20 | 52 | 15 | 1.1 | 0.5 | 15.94 | 7.88 | 0.142 |

| 6305 | 25 | 62 | 17 | 1.1 | 0.5 | 22.38 | 11.49 | 0.22 |

| 6306 | 30 | 72 | 19 | 1.1 | 0.5 | 27 | 15.19 | 0.3498 |

| 6307 | 35 | 80 | 21 | 1.5 | 0.5 | 33.36 | 19.21 | 0.4542 |

| 6308 | 40 | 90 | 23 | 1.5 | 0.5 | 40.75 | 24.01 | 0.6394 |

| 6309 | 45 | 100 | 25 | 1.5 | 0.5 | 52.86 | 31.83 | 0.8363 |

| 6310 | 50 | 110 | 27 | 2 | 0.5 | 61.86 | 37.94 | 1.0822 |

Chemical Composition(%) | ||||||

STEEL NO | C | Si | Mn | P | S | Cr |

GCr15 | 0.95-1.05 | 0.15-0.35 | 0.25-0.45 | 0.025 | 0.025 | 1.40-1.65 |

| Manufacturer | Brand name | Basic type grease | Operation temp.c | Use |

| Exxon | Beacon 325 | synthetic grease | -55~120 | General purpose grease |

| Mobil28 | (Mil-G-81332) | Synthetic hydrocarbon | -55~180 | Wide temperature range,good low temperature torque |

| Chevron | Mineral grease | -30~180 | High temperature range with good water resistance | |

| Shell | Alvania2 | Mineral grease | -35~120 | Long life and wide application |

| KYODO | SRL | Synthetic grease | -40~150 | Low noise,low torque and special case |

| Mobil | HP | Lithium complex | -30~110 | Vibration,moderate speeds and good corrosion resistance |

| Tianjin Hangu | Motor No.2 | Mineral grease | -30~110 | wide application,general purpose |

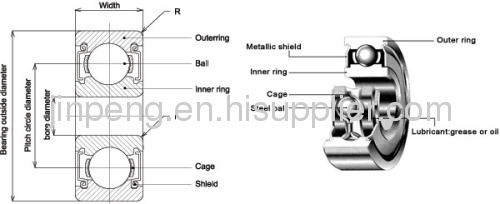

Category: Deep groove ball bearing 6300 series